Basic introduction of prefabricated branch cables

Release time:

2022-05-24

Origin:

Author:

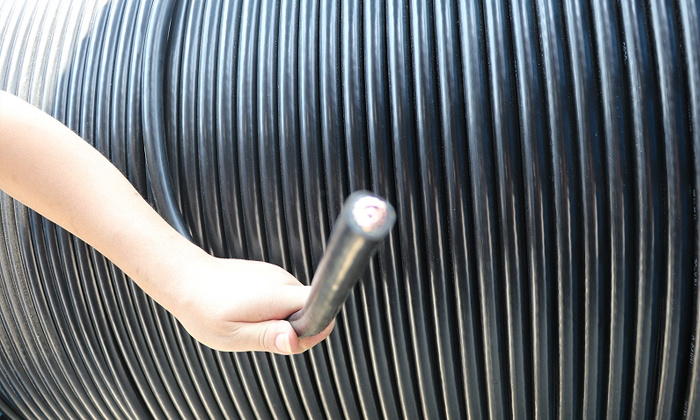

Prefabricated branch cables are manufactured on the production line of specialized chemical factories, equipped with professional production equipment and various special molds. The manufactured branch joint joint is effectively bonded to the original outer sheath layer of the main and branch cables into a whole. As a result, compared to traditional on-site machining of cable branch joints or more advanced busbar trunking processes, the following advantages:

1) Greatly reduces the cost of insulation treatment of branch joints;

2) On-site construction costs are greatly reduced;

3) On-site construction period and time are greatly shortened;

4) On-site construction personnel and equipment are reduced; construction personnel skill requirements are reduced;

5) Not limited by the construction site space and environmental conditions;

6) The insulation function of the branch joint is the same as the main body of the cable, the insulation function is superior, and the reliability is high;

7) It has higher shock resistance, water resistance and fire resistance;

8) The power supply is safe and reliable, and the one-time effective opening rate can reach 100%;

9) Wide range of applications, many varieties and specifications;

10) Users can easily choose cables of various specifications, models, cross-sections and lengths, and the main and branch cables can be arranged arbitrarily;

11) It has more intuitive protection operability.

With the strong growth of my country's national economy, the development of various infrastructure, capital construction, and real estate has accelerated, and the use of power cables as various buildings, equipment, supply, distribution, and trunk lines is a historical necessity. Therefore, construction units, planning units, and construction units are all looking for more advanced, more economical, better functions, smaller effective space occupation, and shorter construction periods. Power supply and distribution construction skills and methods. It is also under such historical environmental conditions that prefabricated branch cables have made great progress in the construction and electrification stages of our country.

1) In terms of medium and high-rise buildings, prefabricated branch cables can be widely used in various medium and high-rise buildings such as residences, office buildings, office buildings, commercial buildings, teaching buildings, and scientific research buildings. , as the backbone cable for power supply and distribution. use;

2) Trunk cables used in airports and ports as airport runway lighting, port terminal lighting, building equipment power supply and lighting;

3) It can be used as tunnel lighting power supply; it can be used as lighting and power supply network in underground mines;

4) In the reconstruction and construction of the urban power grid, the underground or overhead method can be used as the main power cable;

5) In modern standard workshops, used as backbone power cables;

6) In various buildings, equipment, buildings, halls, halls, research institutes, and even sports equipment, swimming pools, etc., it can be used as the main power cable;

7) Other occasions where power cables are used, such as the main lines of power systems such as ships and ships, can use prefabricated branch cables.

machining,branch, processes

Relevant information

"Quality" is an indispensable item on the road to success in the wire and cable industry!

The wire and cable industry is a good opportunity given by this era. It is a pity that the technology and products of some companies cannot keep up with the market. Although they can make profits in a short period of time, it is difficult to form a scale and a brand. In the face of opponents, "quality" has become the top priority of China's wire and cable industry.

2022-05-24

The following conditions should be met before the control cable is installed?

The following conditions should be met before the control cable is installed? If the insulation resistance of the cable core we use does not reach the specified resistance value, it is called poor insulation. This usually happens because, before welding, the cable is not well handled due to moisture, which causes the cable to get wet, which causes the insulating paper to become moldy or deteriorated, thereby reducing the insulation resistance.

2022-05-24

【Increase knowledge】What is the reason for the heating of the cable? How to buy power cables?

When the power cable is under load current, the cable temperature is always higher or exceeds the allowable operating temperature, if the cause is not identified and rectified in time, the cable will continue to run, resulting in thermal insulation failures, short circuit trips and fires. Power cable manufacturers understand that, in use, cable heating can be caused by:

2022-05-24

What is rigid mineral insulated cable? What models and advantages are there?

Advantages of mineral insulated cables: 1. Excellent fire resistance is the main feature of mineral insulated cables. Since the cable is composed of inorganic substances (metallic copper and magnesium oxide powder), it will not cause fire, and it is impossible to burn or support combustion. This is a true fireproof cable.

2022-05-24