How to prevent cable damage in winter

Release time:

2022-05-24

Origin:

Author:

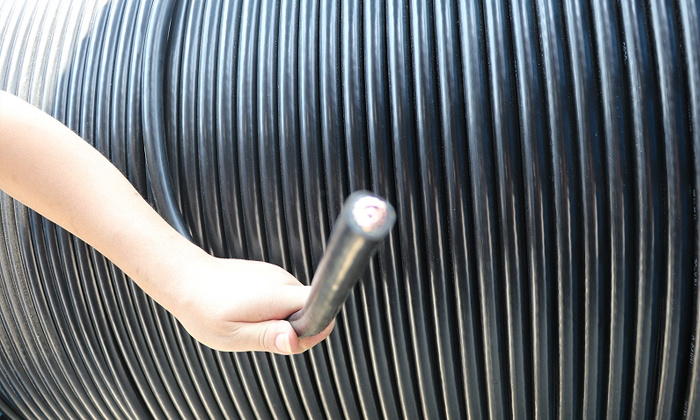

In fact, it is not the quality of the product itself that has any problem, but is caused by the severe cold in winter. The outer skin of wire and cable products is mostly general plastic (PVC) or rubber. When they are in a sub-zero environment, they will become hard, and the entire wire and cable product line will become hard and brittle, resulting in the outer skin may be in the case of thin external force. Fall damage will occur. In winter, especially in northern regions, the outdoor temperature is often below zero, and the surface temperature may be lower. Therefore, if the wire and cable products are placed outdoors or directly on the ground, it is likely that the outer skin of the product will fall. So, how do we prevent the phenomenon of falling wire and cable sheaths in winter? The following methods are adopted from each stage--

1. Delivery from the factory: When the product is loaded on the delivery tool from the factory, it needs to keep warm and protect it. For example, use a closed transport tool to prevent the product from being directly exposed; put a layer of soft cushion on the product, such as a quilt or other soft foam; big.

2. When arriving at the destination or the construction site, the product supplier should send personnel to supervise to prevent rough operation when the product is unloaded.

3. Storage: It is best to store the product indoors, and lay a layer of isolation layer on the storage surface, such as wood, bedding, foam, etc., to prevent the product from being frozen and damp, and pay attention to prevent the product from directly touching the ground. If the cable sheath is scratched, handle it with care.

4. When laying the product: it is best to choose to work when the temperature is warm in the middle and afternoon. If there is a condition, you can use the heater and other equipment to "warm up" the product in advance before use, so that the product can reach the best functional condition. . If it is buried, a protective layer, such as fabric and foam, can be laid in the cable trench in advance. If it is a pipe, make sure that the inside and outside of the pipe is smooth beforehand, so that the wire will not be scratched. Special attention should be paid to iron pipes. When purchasing high-quality iron pipes, there may be many sharp protrusions in the low-quality iron pipes, which may scratch the outer skin of the wires.

5. Select low-temperature cables and test them in strict accordance with the test requirements of the national standard "GB/T2951.14-2008", place them in an environment of minus 35 ℃ for 16 hours, and then perform mechanical function tests, and perform repeated bending and flexing to prevent insulation. And the sheath is tested for elongation and tensile strength, and the pass rate is 100%. Puguang low temperature cable has a strong low temperature resistance function, and can still ensure no cracks in the insulation and sheath skin in the cold external environment. No cracking condition.

phenomenon,following,adopted

Relevant information

"Quality" is an indispensable item on the road to success in the wire and cable industry!

The wire and cable industry is a good opportunity given by this era. It is a pity that the technology and products of some companies cannot keep up with the market. Although they can make profits in a short period of time, it is difficult to form a scale and a brand. In the face of opponents, "quality" has become the top priority of China's wire and cable industry.

2022-05-24

The following conditions should be met before the control cable is installed?

The following conditions should be met before the control cable is installed? If the insulation resistance of the cable core we use does not reach the specified resistance value, it is called poor insulation. This usually happens because, before welding, the cable is not well handled due to moisture, which causes the cable to get wet, which causes the insulating paper to become moldy or deteriorated, thereby reducing the insulation resistance.

2022-05-24

【Increase knowledge】What is the reason for the heating of the cable? How to buy power cables?

When the power cable is under load current, the cable temperature is always higher or exceeds the allowable operating temperature, if the cause is not identified and rectified in time, the cable will continue to run, resulting in thermal insulation failures, short circuit trips and fires. Power cable manufacturers understand that, in use, cable heating can be caused by:

2022-05-24

What is rigid mineral insulated cable? What models and advantages are there?

Advantages of mineral insulated cables: 1. Excellent fire resistance is the main feature of mineral insulated cables. Since the cable is composed of inorganic substances (metallic copper and magnesium oxide powder), it will not cause fire, and it is impossible to burn or support combustion. This is a true fireproof cable.

2022-05-24